Choosing the right pair of work boots shouldn’t feel like deciphering an ancient language, but honestly, with all the acronyms—ASTM, EH, MT, PR—it often does. Your work boots are the armor for your feet, and grabbing the wrong pair based on a confusing label won’t just leave you uncomfortable; it could lead to a serious injury.

As someone who deals with safety standards and job site realities, my goal here is simple: cut the fluff, translate the codes, and help you find the boots that actually protect you from the specific hazards you face every day.

Here is a breakdown of the eight essential types of safety work boots and what those crucial tags really mean.

work boots explained

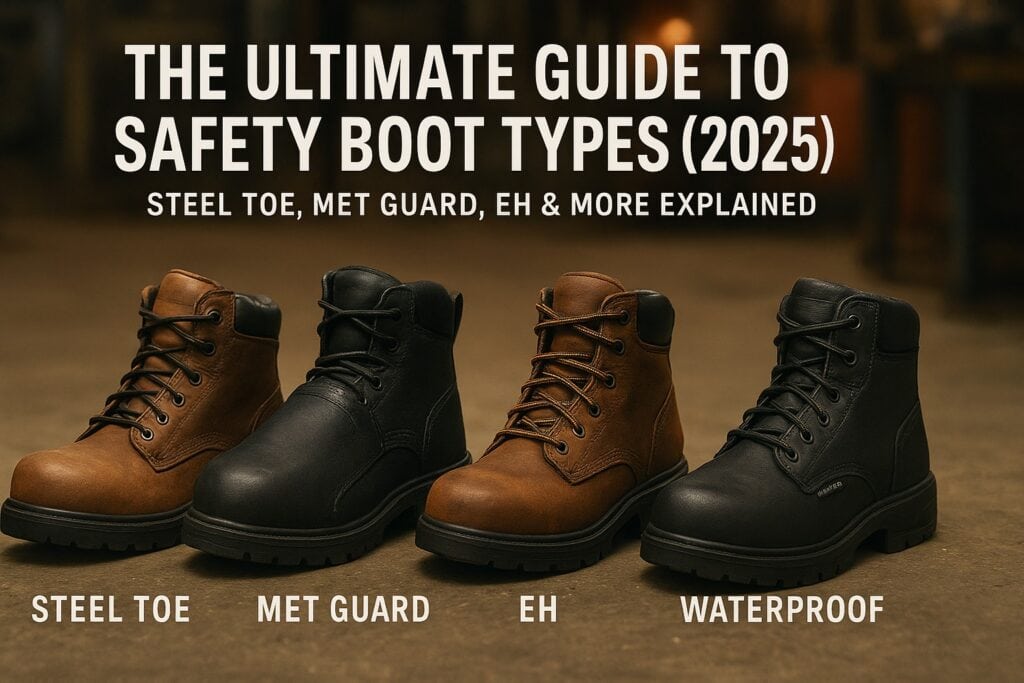

The Big Three: Safety Toe Types Explained

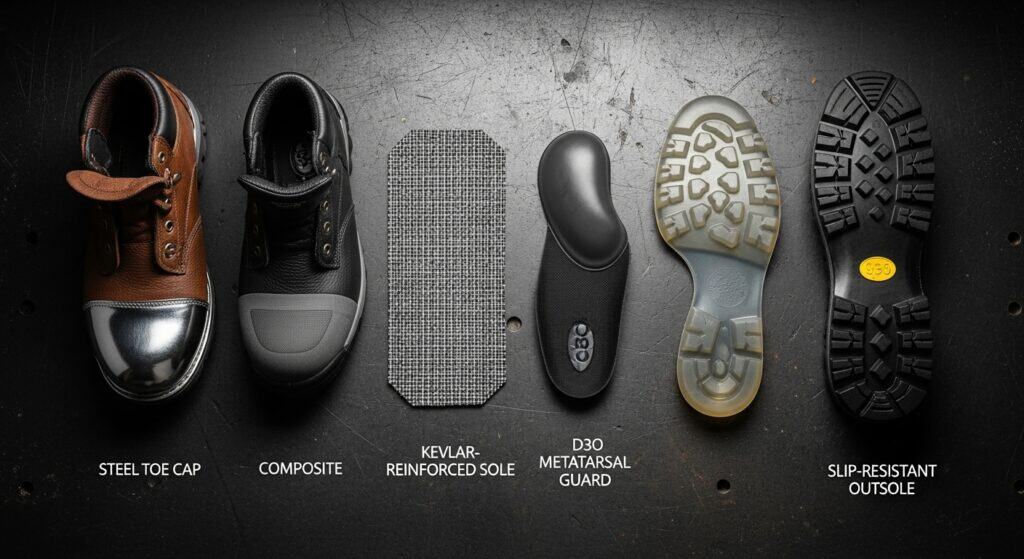

The most common decision you face is which kind of safety toe cap you need. Remember, to earn the high safety rating (I/75 and C/75) in the US, all three types must pass the exact same impact and compression tests, meaning they are equally strong on paper.

1. Steel Toe (The Classic Tank)

Steel toe boots have been the traditional standard for decades, offering reliable protection in heavy-duty environments.

| Pros | Cons |

|

|

Best For: Manufacturing, general construction, and railroad work.

2. Composite Toe (The Lightweight & Non-Conductive Pick)

Composite toes are built using non-metallic materials like fiberglass, carbon fiber, or Kevlar®.

| Pros | Cons |

|

|

Best For: Electricians, utility workers, and anyone working in cold climates or passing through security.

3. Alloy Toe (The Sleek Hybrid)

Alloy toes use lightweight metals like aluminum or titanium. They aim to give you the best of both worlds.

| Pros | Cons |

|

|

Best For: Warehouse pickers, industrial jobs, and delivery drivers who need safety compliance but prioritize lightweight comfort.

Beyond the Toe: Specialized Protection Features

safety boot types

A safety toe is just the beginning. The real hazards on your job site often require special features certified by specific codes found on the boot’s tongue tag.

4. Metatarsal Protection (Mt)

metatarsal guard boots

A standard safety toe only protects your toes. If a heavy object drops further back—on the middle of your foot where the five delicate metatarsal bones are—you’re at risk.

- What it is: A protective shield covering the top of the foot (the metatarsals).

- The Code: Look for MT/75 on the tag. This certifies the guard can withstand a 75 foot-pound impact.

- The Difference:

- External Guards: The “old-school” protective flap. Best for maximum protection and deflecting sparks/molten metal, though they can be bulky.

- Internal Guards: The “modern” choice, often using flexible, impact-hardening foam (like D3O® or PORON XRD®) that is comfortable for walking but instantly firms up on impact.

Best For: Welders, miners, heavy equipment operators, demolition, and high-impact workplaces.

5. Electrical Hazard Resistance (EH)

electrical hazard resistance (eh)

If you work around live wires, incidental contact is a real risk. You need a specialized sole to act as a secondary defense.

- What it is: The outsole and heel are made from non-conductive, shock-resistant materials designed to prevent your body from completing an electrical circuit.

- The Code: EH must be explicitly marked on the boot tag.

- The Test: EH-rated footwear must withstand 18,000 volts at 60 hertz for one minute in dry conditions.

Honesty First: This is secondary protection, not a substitute for proper electrical PPE. You can wear EH-rated steel toe boots; the insulation comes from the sole, not the toe cap.

Best For: Electricians, utility workers, and maintenance staff.

6. Puncture Resistance (PR)

puncture resistance (pr)

Walking over demolition debris, sharp scrap metal, or rusty nails is a major foot hazard.

- What it is: A puncture-resistant plate built permanently between the insole and outsole.

- The Code: Look for PR on the boot tag.

- The Test: PR footwear must resist a minimum puncture force of 270 pounds.

- The Material: Can be a steel midsole (thinner, better against tiny objects) or woven fabric (like Kevlar/Aramid), which is more flexible, lighter, and covers the full footbed.

Best For: Roofers, demolition workers, recyclers, and new construction sites.

7. Waterproof and Insulated Features

If your job takes you outdoors into wet, cold, or muddy conditions, these are essential.

- Water-Resistant vs. Waterproof: “Resistant” repels light moisture. “Waterproof” blocks water penetration using sealed seams, rubber, or a waterproof membrane (like GORE-TEX®). Waterproof boots retain more heat, which can be a pro or a con depending on the weather.

- Insulation: Uses materials (often measured in grams, like 200g or 400g Thinsulate™) to provide thermal protection against the cold.

Best For: Construction crews, utility workers, and anyone working in wet, outdoor, or cold climates.

8. Static Dissipative (SD) and Conductive (Cd) Properties

static dissipative (sd) and conductive (cd) properties

These specialized boots deal with static electricity. They are critical in controlled environments.

- Conductive (Cd) Footwear: Quickly transfers static electricity from the wearer to the ground to prevent a static spark that could ignite explosives or volatile chemicals. (Very low electrical resistance).

- Static Dissipative (SD) Footwear: Controls the rate at which static electricity is bled off the body. This is crucial for protecting sensitive electronic equipment from static discharge. (Controlled range of resistance).

Best For: Electronics manufacturing, computer labs, volatile material handling.

Quick Guide: How to Read the Safety Tag

how to read the safety tag

All footwear certified to the US standard ASTM F2413 must be clearly marked on the tongue or gusset.

| Example Tag Line | Meaning (The Translation) |

|---|---|

| ASTM F2413-18 | Identifies the mandatory US standard and the year it was issued. |

| M I/75 C/75 | M (Male, or F for Female). I/75 (Impact Resistance, 75 ft-lbs). C/75 (Compression Resistance, 2,500 lbs). |

| PR / Mt75 / EH / SD | Identifies special protections: PR (Puncture Resistant), Mt75 (Metatarsal Protection), EH (Electrical Hazard), SD (Static Dissipative). |

Practical Tip: If the boot tag doesn’t list the code (EH, PR, Mt, etc.), it means the boot is not certified for that specific protection, regardless of what the marketing says.

Honesty First: Practical Buying Advice

- Assess Your Hazard First, Comfort Second: Don’t just buy a “safety boot”—buy the right one for your specific job. If you’re a heavy equipment operator, you need the Mt rating. If you’re an electrician, you need the EH rating.

- Fit is King: The safety caps don’t stretch. Ensure you have enough toe room right out of the box. Look for ergonomic designs and cushioned insoles to reduce fatigue.

- Replace After Impact: This is the most crucial piece of advice. If a heavy weight drops onto your steel, alloy, or composite toe, the internal structure may be compromised. The boot cannot protect you a second time. Retire that pair immediately.

- Look for S-Codes (European Standard): You may also see boots rated S1, S2, S3, S4, or S5. These follow the European EN ISO 20345 standard. S3 is very popular as it includes a safety toe, antistatic properties, heel energy absorption, water resistance, and puncture resistance. S5 is the same, but for a fully molded polymer boot (like a Wellington).